|

Clamping System

|

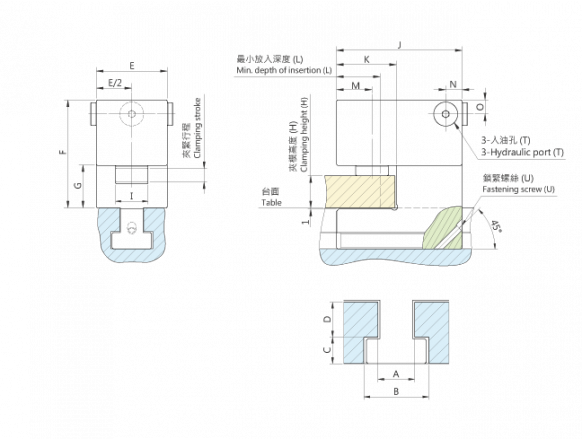

TC Series

Features & Advantages

- Driven by hydraulic pressure directly to the piston

- Wide range of clamping stroke and various applications

- Easy installing and operating

- Adjust the position in the T-slot according to die dimensions

- Fastening screw helps fixing the position

- Operating temperatures up to 70°C

Download

|

Application

TC clamps can be inserted into T-slot manually on the press or injection molding machine to clamp the die at its flat edge. The clamp is suitable for the situation when the available space is limited.

Model (TC-xxM)

|

TC |

xx |

M |

|

Hydraulic Clamp |

Capacity |

No symbol:standard ► for press machine

M:with handle ► for injection molding machine |

Specification

|

Item |

Unit |

TC-01 |

TC-02 |

TC-03 |

TC-04 |

TC-06 |

TC-10 |

TC-16 |

TC-25 |

|

Clamping force(250kg/cm2) |

(tf) |

1 |

1.5 |

2.4 |

4 |

6 |

10 |

16 |

25 |

|

Oil consumption |

(cm3) |

5.4 |

7.4 |

12.2 |

26.6 |

39.4 |

65.1 |

155.9 |

228.5 |

|

Weight |

(kg) |

1.6 |

2.6 |

3.8 |

5.4 |

8.4 |

16.8 |

30 |

52 |

|

Clamping stroke |

(mm) |

8 |

12 |

16 |

|

Max. H |

(mm) |

35 |

40 |

40 |

45 |

55 |

60 |

70 |

75 |

|

Min. H |

(mm) |

20 |

25 |

25 |

25 |

35 |

40 |

45 |

50 |

|

E |

(mm) |

43 |

50 |

58 |

65 |

80 |

100 |

136 |

160 |

|

F |

(mm) |

G+43 |

G+49 |

G+55 |

G+60 |

G+65 |

G+82.5 |

G+98 |

G+105 |

|

G |

(mm) |

H+9 |

H+13 |

H+17 |

|

I |

(mm) |

Ø16 |

Ø18 |

Ø24 |

Ø30 |

Ø37.5 |

Ø50 |

Ø62 |

Ø80 |

|

J |

(mm) |

75 |

91 |

103 |

115 |

130 |

165 |

220 |

255 |

|

K |

(mm) |

33 |

43 |

48 |

55 |

65 |

83 |

114 |

135 |

|

L |

(mm) |

27 |

30 |

35 |

40 |

48 |

60 |

80 |

100 |

|

M |

(mm) |

21.5 |

25 |

28 |

32.5 |

40 |

49 |

68 |

80 |

|

N |

(mm) |

13 |

16 |

18 |

15 |

14 |

21 |

52 |

58.5 |

|

O |

(mm) |

10.5 |

12 |

13 |

13 |

14 |

20 |

18.5 |

21 |

|

T |

(inch) |

Rc 1/8 |

Rc 1/4 |

|

U |

(mm) |

M5 |

M8 |

M10 |

M12 |

M16 |

Note

- Customized clamping height is available on request

- Specify T-slot dimension (A, B, C, D) and die height when ordering

Accessories

Bracket

Handle

|